Media Releases

A DVC with Design in Mind

Media Releases

Professor Chris Rudd OBE, Deputy Vice Chancellor (DVC) and Head of Campus, Singapore, remains a researcher at heart.

For senior university leaders it can be a challenge to strike a balance between forging a strategic academic leadership base and maintaining an active presence in research [1]. Not so for the new DVC of James Cook University in Singapore, who maintains equilibrium between both of these key aspects of his academic career.

Professor Rudd trained in Mechanical Engineering and has researched the mechanics and manufacturing of fibrous composite materials for more than 30 years.

“As an undergraduate I was lucky enough to get an internship in a prestigious National Lab in the UK and joined a group developing some of the early applications of carbon fibre for engineering structures. I was fascinated by the idea of “designer materials” that could be tuned by changing fibre orientations to optimize performance for a given type of loading”, he said

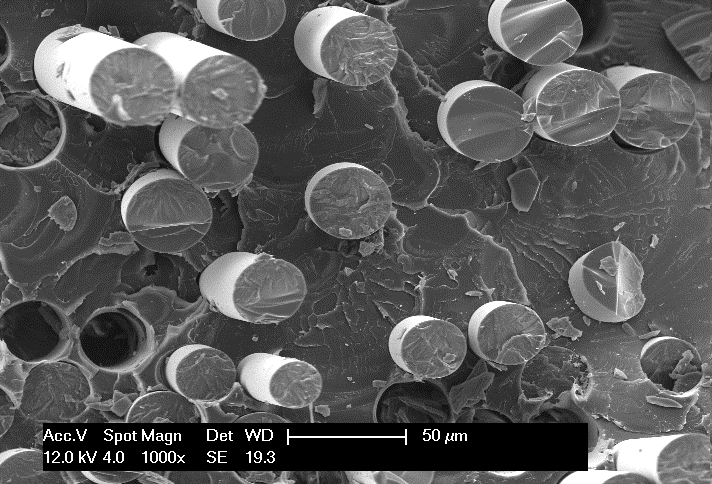

(Left) Electron Microscope image of a fracture surface from a composite structure showing cylindrical glass fibres embedded in a polymer resin matrix. Under load, the fibres carry almost all of the forces and thereby make the composite much stronger than the polymer alone. [proprietary image, Rudd group].

(Left) Electron Microscope image of a fracture surface from a composite structure showing cylindrical glass fibres embedded in a polymer resin matrix. Under load, the fibres carry almost all of the forces and thereby make the composite much stronger than the polymer alone. [proprietary image, Rudd group].

Professor Rudd then signed up for a PhD at Nottingham, sponsored by Ford Motor Company and was to spend the next 10 years building a large team to develop and commercialise technologies for making auto bodies from lightweight composite materials. He later drew in collaborators from the marine and aerospace industries and led many collaborative projects to improve understanding of the physics and chemistry of manufacturing in order that cycle times could be reduced, waste and scrap eliminated and the industry could improve its profitability and environmental credentials. The team worked on many commercial applications of these new materials including the Aston Martin Vanquish – the so-called “James Bond Car”.

(Right) Skull model showing typical (metal) boneplates used in maxillofacial surgery repairs to assist fracture healing. The aim of the research is to develop resorbable polymer composite alternatives that accelerate healing and don’t need to be removed via surgery. (public domain image)

(Right) Skull model showing typical (metal) boneplates used in maxillofacial surgery repairs to assist fracture healing. The aim of the research is to develop resorbable polymer composite alternatives that accelerate healing and don’t need to be removed via surgery. (public domain image)

“As I became increasingly involved in University-level management it became increasingly difficult to find the time to lead such a large group effectively and satisfy a set of demanding industrial sponsors. At the same time I felt the need for fresh challenges in research and decided to switch the main thrust of my work to biomedical devices that could exploit the unique properties of fibre composites”, shared Professor Rudd.

Thus began a 15 year adventure that led to the development of a new type of glass fibre that could be tolerated inside the human body and would encourage the attachment and proliferation of bone cells. Professor Rudd’s team also learned how to control the rate at which the fibres would dissolve in order to produce resorbable materials that could be used for repairing bone fractures or craniofacial reconstruction. The technology is the basis for a string of international patents, several of which have been licensed to industry. Professor Rudd has supervised more than 50 PhD students to successful completion and has co-authored around 170 journal articles.

In China, Professor Rudd’s expertise was in great demand. He attracted Government sponsorship to create the Ningbo New Materials Institute, where around 100 researchers are now developing new high performance materials for energy storage, conversion and lightweight structures. He set up a joint laboratory with Aerospace giant AVIC on sustainable composites and attracted funding from both Chinese industry and multinational companies.

How does Professor Rudd’s research agenda chime with activities at JCU?

Drawing on his decades of experience as a strategic leader, he explains as follows: “My first hope is that some of the ways of working that I have evolved over the years could bring some benefit to JCU – working in a group, sharing resources, bringing in industry and business. I also hope that I can lead by example and do my best to boost JCU’s performance in research and knowledge exchange. One interesting opportunity is to investigate some of the fascinating plant fibres which abound in South-East Asia in order to find new and sustainable sources of strong reinforcement materials. I am also keen to link with the leading researchers at James Cook University campuses in Australia and look forward to using my upcoming trip to Cairns and Townsville to forge some new links.”

Contacts

Research: researchdean-singapore@jcu.edu.au

Media: pinky.sibal@jcu.edu.au